Engine Radiator Repair – Essential Knowledge

There are various methods to “repair” radiators, but not all are beneficial for the radiator’s longevity. Whether you’re considering a DIY repair or simply curious about the process, we will explain our approach to radiator repairs.

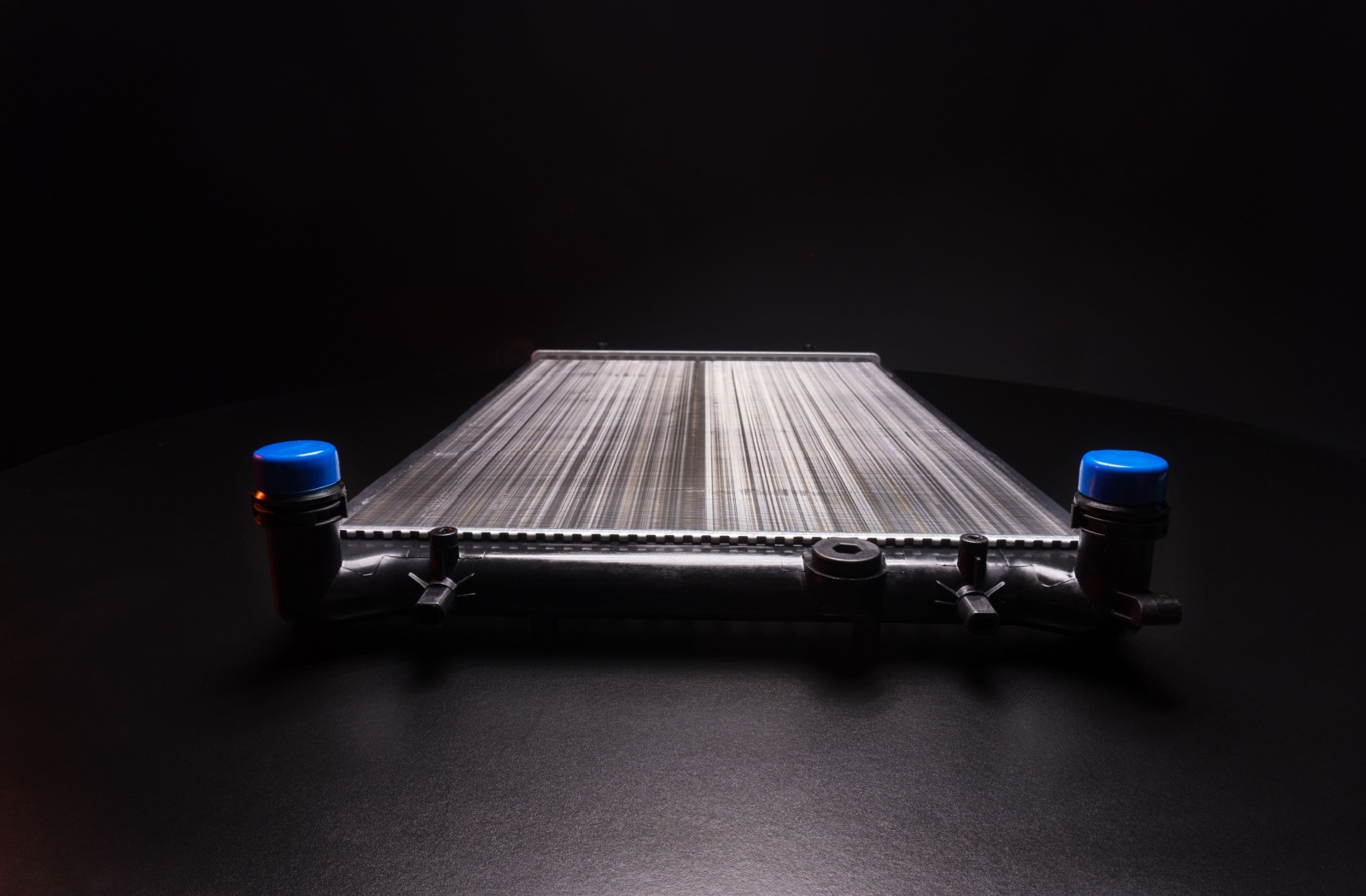

Understanding the differences between radiator types is crucial, especially between those made of copper-brass and aluminum. Aluminum radiators cannot be repaired in the same manner as copper-brass ones. The tank type and leak location are also critical factors. Here are some initial steps to take before proceeding with any repairs.

Material Identification

Radiators typically feature a core made of aluminum or copper-brass. Tank materials may include aluminum, plastic, or brass, depending on the core’s composition. The material dictates the most appropriate repair method; some radiators can be fixed, while others must be replaced.

Leak Identification

Locating the leak may seem straightforward, but precise identification is vital. If antifreeze is pooling beneath your vehicle, pinpointing the exact leak source is necessary. A leaky radiator hose, as opposed to the radiator itself, represents a simpler repair. Watch out for common failure points such as:

– Tank Connections (welded, bolted, etc.)

– Radiator Tubes (the elongated tubes spanning the radiator’s length)

– Header Plates (where the tubes meet, and tanks are connected)

In addition to finding the leak, understanding its cause is imperative. Some types of damage are irreparable, necessitating radiator replacement. Look out for signs such as:

- Significant damage to metal, such as tears, large holes, or bulging,

- along with pinhole leaks,

- separation of the tank from the core, and

- obvious corrosion,

Above all indicate that a radiator replacement is necessary. If the tanks are intact, re-coring the unit may be an option. However, even pinhole leaks suggest internal corrosion, making re-coring a consideration.

What Not to Do

Many makeshift solutions for a leaking radiator are circulating, but they are not viable long-term fixes. Here are some methods to avoid:

- Cutting and crimping a damaged radiator tube may seem like a quick fix, but it compromises the radiator’s cooling capacity. This action can disrupt coolant flow, increase system pressure, potentially cause other failures, and lead to overheating. Additionally, there’s a risk of further damage to adjacent tubes and fins.

- Adding pepper to the radiator to seal pinhole leaks introduces contaminants into the coolant, which can circulate through the engine and cause further issues. This method is ineffective as a permanent solution.

- Patch welding an aluminum radiator might appear to be a solid repair, but it’s a temporary solution at best. The underlying issue is metal fatigue, which means the radiator needs replacing. Even if the weld holds, other weakened areas may soon fail.

Whenever your tanks become damaged, it’s advisable to replace them. They are vital for the proper functioning of your radiator and taking a chance on a repair that may not hold or on unseen damage causing further issues later is not recommended. If the damage has resulted in fragments of the tank within the radiator, a complete flush is necessary to remove all debris. Should you be unable to clear the debris, radiator replacement is essential to avert severe engine damage in the event of radiator failure.

Copper-brass radiators are the only type that can be effectively repaired. Their solder-based construction allows them to be disassembled, cleaned, and re-soldered. This is feasible only if the damage is not extensive. If there are leaks around the header plates or at the points where tubes meet the headers, cleaning and repairing the radiator can be an effective solution. However, it’s important to note that copper-brass radiators require frequent maintenance and repairs due to ‘solder bloom,’ a phenomenon where the solder that secures the tubes to the headers builds up, potentially blocking flow and causing pressure build-up, tube bursts, and overheating. Solder bloom is inevitable due to the interaction of the different metals used.

To minimize the need for repairs, it’s best to follow the adage that “an ounce of prevention is worth a pound of cure.” Regularly changing the coolant as per the recommended schedule is one of the simplest preventive measures. Over time, corrosion inhibitors and other protective additives in the coolant degrade. Although the coolant retains its heat transfer capability, the interior of your radiator and engine can incur damage from the depletion of these additives, which underscores the importance of timely coolant replacement.

Some of these steps are doable on your own; however, the chemical bath involves hazardous chemicals that are best avoided. Moreover, if you lack extensive experience with soldering, it’s advisable not to attempt re-soldering the unit yourself, as it requires skill to achieve a reliable finish. The paint we utilize is specifically designed not to insulate the radiator, unlike many others. Ultimately, repairing a radiator is futile if it cannot dissipate heat due to insulating paint.

Call Our Team About Your Radiator Today

Timely maintenance and repairs are essential for the longevity of your aluminum radiator and overall engine health. By understanding the causes of damage, exploring repair options, and knowing when to replace, you can make informed decisions that save money and benefit the environment.Schedule an inspection today if you are unsure about the condition of your radiator. Our expert team at City Wide Radiator can offer tailored advice to prevent future damage and ensure your vehicle runs smoothly.